Regardless of how good your quality assurance is, something will inevitably go wrong. A concrete truck gets held up in traffic and is 5 minutes longer than the allowable batch to pour duration; a shower of rain affects the surface of a new concrete pour; or a gravel lot falls slightly out of grading spec. This is when a good non-conformance system comes in to play.

Contrary to the old-school perception that a non-conformance is a bad thing, NCRs are actually a sign of a quality assurance system that is working. A reliable NCR system gives clients confidence that any issues on site are being identified and resolved in a manner where the final quality of the project is not compromised.

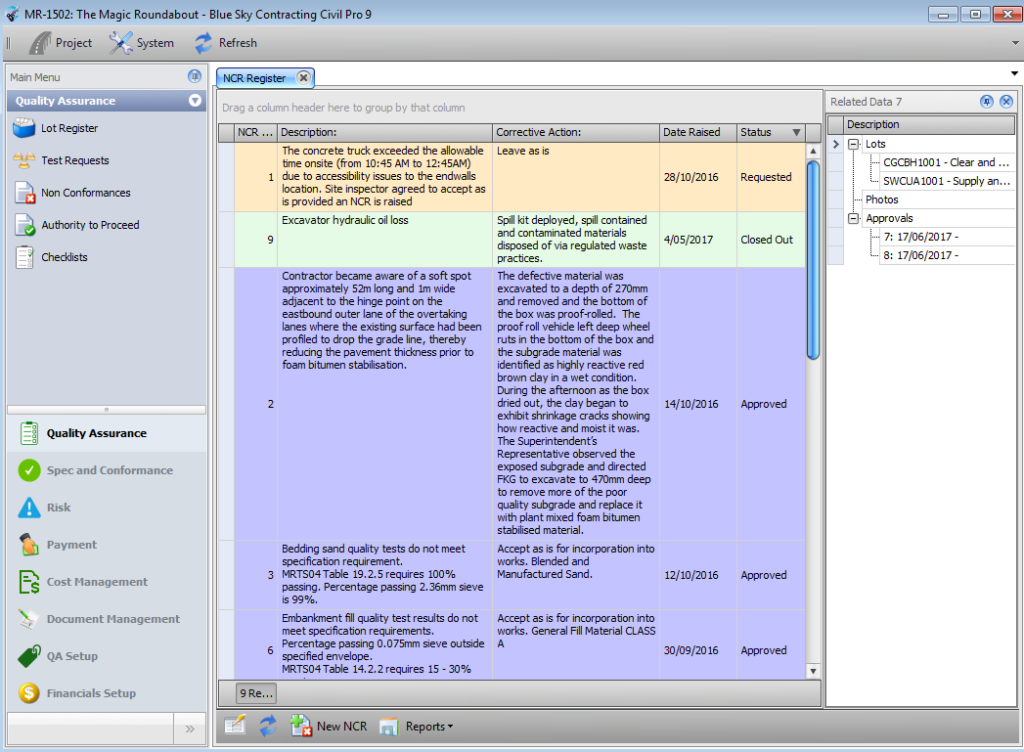

Civil Pro’s NCR Register tracks issues with process or product, recording key details about the problems and tracking their resolution. Our NCRs:

- define the issue

- specify corrective action

- propose action to prevent re-occurrence of the issue

- record the approval of the NCR by the client (or other party)

- track the closeout of the issue – once approval for a course of action is gained, is that course of action completed?

- allocate properties for NCR management such as the Action Type (Retest; Repair/Rectify; Replace/Reconstruct; Use As Is etc.), severity, related properties and root cause

One of the implications with NCRs is that they can, under some Specifications, prevent payment for work. Civil Pro assists in monitoring the impact of NCRs in this environment by calculating the cost impact of NCRs, thus allowing prioritisation of NCR closeout and quantification of the metric for reporting purposes. NCR value is calculated based on the value of Lots linked to the NCR (from any Lot Quantities). This can be viewed using the predefined NCR Value view of the Register.